Engineered for the automotive industry

At CQFD Composites, our mission is to develop innovative composite solutions based on our structural thermoplastic pultrusion technologies.

For the Automotive market, we have developed =C–SHOCK®.

=C–SHOCK® material range is a pultruded thermoplastic composite material with extremely high fibre content (up to 70% by volume) combined with a high molecular weight PA6 designed for semi-structural automotive application.

=C–SHOCK® exhibits high stiffness and strength with an excellent specific rigidity (stiffness over weight ratio). Recyclability, post shaping ability as well as over-moulding possibilities are valuable properties to engineer novel structural parts of tomorrow’s vehicles.

For the Automotive market, we work hand to hand with Tier One suppliers and Car Manufacturers on innovative product concepts.

Key benefits of =C–SHOCK®

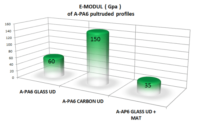

=C–SHOCK® can be obtained with glass or carbon fibre. To optimize the ratio Weight Saving vs Cost, =C–SHOCK® can also be used with an intelligent combination of glass and carbon fibres mixed together at targeted positions in a profile.

Fabrics can also be included to obtain increased transversal properties.

The amazing synergy between a very high content of reinforcement fibres and an extremely well impregnated performance thermoplastic resin give =C–SHOCK® out performing properties above most of all existing material properties.

With experience in others transformation processes such as injection or extrusion, we can propose and develop a multi-process approach to combine the best of several technologies.

Nowadays, the automotive market is strongly looking at thermoplastic composites and has recognised the benefits in developing new products with CQFD Composites state-of-the-art pultrusion technologies and the =C–SHOCK® material range.

A multi-process combination allows from 40% up to 70% weigh saving on similar products traditionally made of steel.

Applications

The use of =C–SHOCK® structural thermoplastic profiles has been proven to be an advantageous approach for the automotive industry when used as structural inserts in more complex plastic parts. In fact, unlike with thermoset, our pultruded insert will easily adhere with the hot melted resin coming from the injection moulding process.

One should consider the composite insert as the mechanical “back bone” of the final part and the injected resin as the “skin” of the product to reach the required complex shape and functionality.

Our =C–SHOCK® pultruded composite formulated for overmoulding shows good adhesion with PA6.

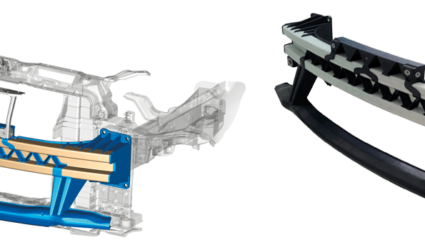

A good illustration of the great possibility of =C–SHOCK® thermoplastic composite profiles is the development made with our partners HYUNDAI and PLASTICOMNIUM on a Front Crash Beam for a sedan vehicle.

Based on =C–SHOCK® curved thermoplastic pultruded insert produced by CQFD Composites, the rest of the beam is then over-moulded by Plasticomnium including crash boxes and lower pedestrian bar.

This concept will advantageously replace a metallic beam with about 40% weight reduction based on glass fibre at equal performances. With potentially lower cost carbon fibres in the coming years, this breakthrough concept will significantly contribute to the weight reduction goals of the Automotive industry to match the energy saving targets.

Another illustration of our =C–SHOCK® range is found in an (confidential) application where high dynamic mechanical solicitations are required. In this case, our composite material has been submitted to high frequency bending stress over more than 20 millions cycles without failure.

With our reactive thermoplastic technologies, the high fibre content does not limit the fatigue behaviour as proven to be the case for most thermoset materials where the fatigue properties drop after a maximum fibre content around 55%.